Chance evaluation methodologies ensure that the maker’s attempts are focused on the parts of optimum risk by addressing vital process parameters and potential failure modes. This transforms QRM into a proactive Device when built-in into process validation.

Process validation performs a vital purpose in high-quality assurance by furnishing assurance that a production process is less than Management and capable of continuously making products that satisfy shopper demands.

Information integrity is another essential facet emphasised because of the EMA. The guidelines stress the necessity of protecting correct, comprehensive, and reputable info all through the validation process. This features making sure right documentation tactics, info traceability, and information integrity checks.

Examine the acceptance conditions and effectiveness check final results, present conclusions over the validity from the tools/procedure, danger management, and gain departmental and good quality assurance approval with using this template.

Transformation of beginning resources into finished solutions by way of a solitary operation or maybe a sequence of functions involving processing products, environmental Manage, personnel and documentation.

in the course of the schedule production. Execution of validation also offers a large degree of assurance of

Batches made for process validation need to be the same dimensions as being the supposed industrial-scale batches. Any use of various batch dimensions have to be justified. Batches ought to only be manufactured by educated staff in accordance with GMP guidelines making use of permitted documentation. click here

Process validation is a vital part of excellent assurance in the production industry. It consists of the gathering and Assessment of knowledge to make sure that a process regularly makes items that fulfill predetermined specifications and high quality specifications.

Be performed in accordance with GMP guidelines, and info needs to be stored at the production area, making it quickly available for inspection functions.

Documentation for concurrent validation mirrors the necessities for potential validation. Each and every stage of the process, from checking to solution screening, needs to be meticulously recorded. This documentation serves to be a regulatory necessity and ensures traceability for upcoming reference or audits.

Think about the tentative boundaries of critical process parameter as well as their Command Restrict pointed out while in the MPS .

Use without spending a dime with compact groups. Unrestricted reports and storage for quality accounts. Review pricing ideas.

Homogeneity in just a batch and consistency among batches are goals of process validation things to do.

Within a get more info highly controlled industry like MedTech, producing processes need to go through both process verification or process validation to guarantee they’re regularly developing the right outcome.

Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Macaulay Culkin Then & Now!

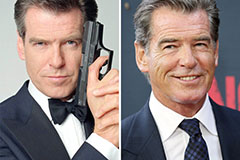

Macaulay Culkin Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!